ARC has been covering Advanced Process Control (APC) for over two decades. Based on this knowledge, ARC analysts have developed a comprehensive set of criteria to help you select the best APC solution available on the market.

The complex nature of manufacturing coupled with the large investments in assets by operating companies in the process industries make the need for automated process control greater than ever. APC, also referred to as Multivariable Predictive Control (MPC), is a proven technology that reduces process variability and inefficiency, improves product consistency, increases throughput by allowing operations to push constraints to the limits and achieve higher return on assets.

Over the years, APC has decisively demonstrated its value as a best practice by increasing throughput and improving yield, energy usage, raw material usage, product quality, safety, and responsiveness.

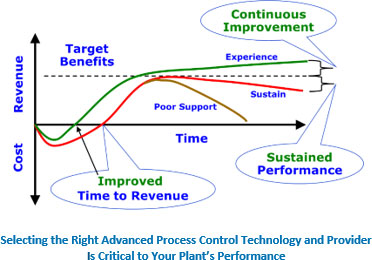

Implementing an APC solution can be time consuming and costly. For instance, many companies typically spend hundreds of thousands of dollars installing an APC solution. Implementation usually involves several lengthy steps such as preconditioning and testing, model building, controller integration, and commissioning. Many suppliers are now offering improved tools that help decrease the time and effort necessary to implement solutions and achieve faster time-to-benefits.

Implementing an APC solution can be time consuming and costly. For instance, many companies typically spend hundreds of thousands of dollars installing an APC solution. Implementation usually involves several lengthy steps such as preconditioning and testing, model building, controller integration, and commissioning. Many suppliers are now offering improved tools that help decrease the time and effort necessary to implement solutions and achieve faster time-to-benefits.

With the availability of more tools and better methodologies, an increasing number of companies are now starting to apply APC to smaller units that were difficult in the past to justify on an ROI basis. In addition, more transition and startup sequencing technology is being integrated with control applications to provide safer and more profitable operations. Incorporating rigorous modeling technology into the controller will also extend its applicable range and accuracy. Advanced control techniques are also finding many applications in batch and semi-batch operations. [Learn more about Advanced Process Control.]

The following are a few of the strategic issues specifically covered in the Advanced Process Control Selection Guide:

The benefits of advanced process control are well documented, for example, reducing process variability, product give away, and optimizing against process constraints. Often such optimization has also been accomplished in silos from other production stakeholders. Today and in the future, especially in downstream refining and chemicals, benefits of steady operation will be managed in real-time against the gap existing between “plan versus actual” and eliminating this loss experienced by production planners and production schedulers. While production optimization is not new, the ability to dynamically coordinate multiple process units in closed loop and automatically adjusting APCs is a market driver. Production optimization software is easily deployed and maintained by APC engineers and often a logical extension of an engineer’s workload.

APC engineers are well positioned to leverage the wave of artificial intelligence, cognitive computing, or prescriptive analytics. While APC technology has been built on a foundation of empirical and first principle models, machine learning and data science are now becoming a profitable lever of performance in the optimization market. Leading suppliers are pushing the peripherals of the process industries. They are now looking to address the performance of static assets and equipment such as pumps, exchangers, distillation columns, and furnaces and how each of these are intertwined to the systemic reliability and performance of process units or hydroprocessing facilities that are front and center in the continuous process and batch process industries.

Today, companies are embracing real-time performance management as a means to improve flexibility and profitability while coping with the reduction of manpower and the burden of monitoring assets. As such, making KPIs visible about the performance of the controller is becoming more common to ensure that it is being effectively utilized. As companies move to the next level of performance by adopting rigorous optimization to augment APC, it is imperative to monitor controller performance to make certain it is operating correctly. Still, more needs to be done in the way of providing KPIs that tie into business objectives and provide actual cash benefit.

For more information on this technology guide or to discuss how we can help you, please contact us.