ARC recently expanded its coverage of the market for multiphase flow metering based on growing demand from owner operators, independent E&P firms and suppliers to develop a quantitative assessment of the market for virtual flow metering (VFM) solutions. Although VFM solutions have been around since the mid-1990s, when MSi Kenny (part of Wood PLC) first started deploying them in the North Sea, there has not been much market coverage of these lower cost and more flexible multiphase measurement solutions. Interest in this growing market segment has only intensified as advancements in advanced analytics, machine learning and modeling simulation software has improved the performance of VFM solutions to the point where they can operate as a backup to a MPFM in the event of a failure or even help calibrate the accuracy of the MPFM itself.

VFM solutions are model-based and extremely flexible with some VFM suppliers indicating they can develop a unique model for each well and by phase of measurement. VFM models can be classified as

The data-driven approach is a system identification tool, which requires the user to accept one of generic model structures. Such models exploit no prior knowledge on the flow and produce essentially data descriptions. In practice, it is easier to setup a data-driven model as compared to a hydrodynamical one. However, data driven predictions do not have a physical interpretation and it is not possible to estimate parameters with no historical data. Data driven VFMs offer the ability to not only predict rates, but also to forecast rates at future time instants. The use of data driven VFMs is gaining greater adoption. It is believed that both approaches require periodic calibration based on actual well testing to compare actual rates from a meter or separator as compared to the model derived rates.

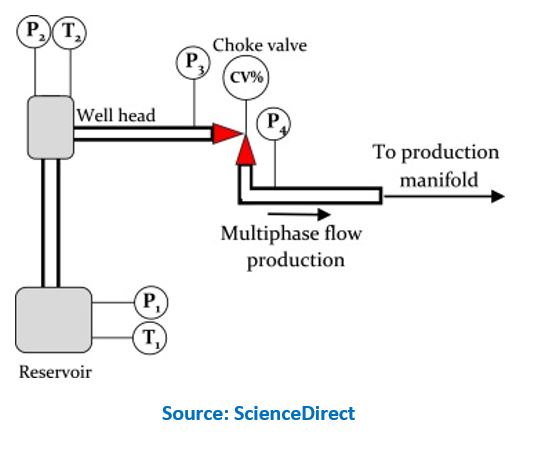

Virtual flow metering (VFM) solutions are software model based and typically rely on conventional pressure, temperature and flow sensors deployed in a wellbore and on production trees in order to model, infer and estimate three-phase well flow rates in real-time. The software is based on models that extend from the reservoir to downstream of the wellhead choke. Usually, there is adequate information/instrumentation available to use multiple independent models to estimate the flow rate. Multiple estimates make predictions more accurate and the technique robust and tolerant to instrumentation failures. Typical measurements used by a VFM include:

Virtual flow meters typically examine the pressure drops naturally occurring in a well and, from that, infers a flow rate and composition based on a set of models. VFM solutions are extremely flexible with some VFM suppliers indicating they can develop a unique model for each well and by phase of measurement. VFM models can be classified as hydrodynamical or data-driven. In the hydrodynamical approach ones typically solves the phase conservation equations in pipe geometry, which requires the choice of an adequate math model, appropriate numerical method, and availability of a large number of input data. An advantage of this approach is that one can estimate various parameters at arbitrary points of the flowline.

The data-driven approach is a system identification tool, which requires the user to accept one of generic model structures. Such models exploit no prior knowledge on the flow and produce essentially data descriptions. In practice, it is easier to setup a data-driven model as compared to a hydrodynamical one. However, data driven predictions do not have a physical interpretation and it is not possible to estimate parameters with no historical data. Data driven VFMs offer the ability to not only predict rates, but also to forecast rates at future time instants. The use of data driven VFMs is gaining greater adoption. It is believed that both approaches require periodic calibration based on actual well testing to compare actual rates from a meter or separator as compared to the model derived rates.

ARC analyzed the main applications for VFM solutions including:

ARC is forecasting robust growth in demand for VFM solutions as they are seen as less expensive complement to MPFM solutions that ensure validation of the MPFM, serves as a backup for an MPFM to ensure reliability and continuity in measurements, are a useful tool for estimating real-time well flow rates, and reduces the need for bulkier and often more expensive test separators.

If you are an owner operator, independent E&P firm or other user we welcome to learn about your experiences, challenges and, if applicable, successes you have had with VFMs for use in your production operations. If you are a supplier that is interested in informing us about how your VFM solution is differentiated from that of other suppliers then we welcome the opportunity to speak. Please feel free to contact me at tshea@arcweb.com .