A digital twin is a dynamic virtual representation of a physical entity using real-world data. The most common

As ARC Advisory Group learned in a recent briefing, the L&T Technology Services (LTTS) Avertle solution is designed to deploy PdM in manufacturing and other industrial environments. Its edge computing is well suited for high-speed processes and conveyor systems. Avertle’s case stories demonstrate a proven track record, making it a viable option for PdM applications.

Unplanned downtime negatively impacts the typical metrics for maintenance. These include asset uptime, asset longevity, cost control, and safety. Improvements start with reducing unplanned downtime, such as when equipment stops working at the most critical time while it is making product for sale.

Research indicates that preventive maintenance and periodic inspections are usually ineffective. This is because 82 percent of assets have a random failure pattern.[1] Digital twins monitor asset health continuously and warn when it deteriorates so the asset can be repaired before failure occurs. Many of these digital twin applications for PdM have evolved to include monitoring operational performance of an asset (throughput, quality, yield).

Your CEO and other senior executives focus on their metrics like revenue and return on assets (ROA).

Several industries have high-speed processes where the data acquisition and associated analytics require edge computing to help prevent unplanned downtime and improve operational performance. A cloud-only solution becomes impractical due to data communication capacity limits, slow response time, network delays, and/or outages. Examples of high-speed processes are found in:

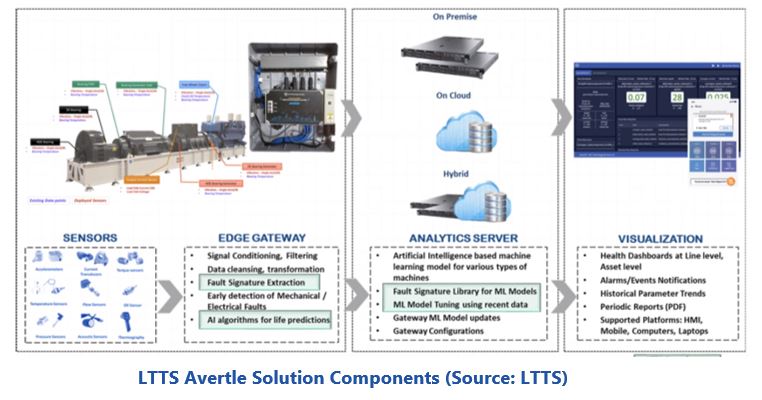

Recently, LTTS executives briefed ARC on its Avertle solution for condition-based maintenance (CBM). As we learned, the solution includes data acquisition, analytics, visualization, and alerts.

The Avertle solution has these principle components:

An alert typically needs some level of evaluation to determine an appropriate action. Several questions need to be answered. Is it valid? Does the operator need additional training? Do we have bad materials? Perhaps the process control system needs adjustment. If it is a maintenance issue, is an electrician, mechanic or other skill needed? This type of evaluation is usually performed by a reliability, process, or control system engineer who would typically use Avertle to review alerts and determine the next steps.

Avertle has successfully reduced unplanned downtime as shown in these customer case stories provided by LTTS.

A leading food and beverage company had excessive unplanned downtime for the filling line in its bottling plant. This is a critical set of assets since downtime directly impacts plant performance, KPIs, and revenue. The existing

Initial success led to a rollout across eight plants in US for 57 assets. The asset types include blow molder, filler & capper, filler & seamer, labeler, packer & palletizer, ammonia chiller, and compressor. The “small data” approach acquires a manageable set of parameters, including current, temperature, and vibration sensors for the specific assets being monitored.

Early failure detection with edge processing reduced data congestion and latency. Increased uptime of the production lines provided a 3 percent increase in production (cases handled). Also, maintenance costs were reduced by 7 percent.

A leading global beverage maker needed to reduce the unplanned downtime of critical assets at the filling station. A failure among the conveyor motors caused an average production downtime of 90 minutes. In addition to reduced production, the downtime impacted the process which led to product losses due to contamination of the liquid.

Avertle was applied in filling stations for the three bottling machines. Sensors on the filler conveyor motor, spray pump, and delivery belt provided current, temperature, and vibration to monitor equipment health. Analytics on the edge for reduced data congestion and latency enabled early failure detection.

The Avertle solution reduced unplanned downtime for these critical assets and avoided production losses with improved product quality and bottling volume. Benefits included improved asset uptime from 80 percent to 93 percent, reduced maintenance cost by 15 percent, and improved production.

Unplanned downtime for critical assets has significant negative business impact on revenue, on-time shipments, asset longevity, and maintenance costs. Effective PdM helps prevent unplanned downtime and improves business performance while also increasing executive KPIs.

The typical LTTS Avertle digital twin applications deploy PdM to help prevent unplanned downtime. As we learned, its edge computing is well suited for high-speed processes and conveyor systems. After installation and some artificial intelligence learning, Avertle applications have achieved 85 to 90 percent of valid alerts. These alerts usually go to engineering to determine an appropriate next step. Avertle has a proven track record and should be considered for preventive maintenance applications.

ARC Advisory Group clients can view the complete report at ARC Client Portal

If you would like to buy this report or obtain information on how to be-come a client, please contact us

Keywords: Predictive Maintenance, Edge Analytics, Avertle, L&T Technology Services, ARC Advisory Group.

[1] “How to Get Executive Support for Digital Twins and Predictive Maintenance”

ARC Strategies, August 2020, by Ralph Rio