At the virtual annual ARC Industry Forum Asia titled Accelerating Industrial Digital Transformation and Sustainability on July 12-14, 2022, Hexagon participated as a Platinum Sponsor. Registrations touched 1,600+ delegates for the two  language tracks – Japanese and English. This ARC View will cover the highlights of the presentations made by speakers from Hexagon in both the language tracks.

language tracks – Japanese and English. This ARC View will cover the highlights of the presentations made by speakers from Hexagon in both the language tracks.

In the Japanese track, Hiroshi Osaka, APAC Business & Operations Director, Asset Lifecycle Intelligence Division, focused on introducing Smart Digital Reality into the Japanese market, which is being promoted globally by the company. In the session on Asset Management Advances, Kevin Price, Vice President, Digital Assets Strategic Advisor, Technical Product Evangelist, spoke about the company’s industry agnostic Enterprise Asset Management (EAM) solution.

Hexagon defines itself as a digital reality company that promotes autonomy for industrial development. The company aims for automation through data utilization and further autonomy. First, looking at the current state of data utilization, which is the basis of autonomy, the amount of data generated has increased exponentially due to the trends of digitization, IoT, and Digital Transformation (DX). On the other hand, utilization of data has not kept pace. Data utilization is achieved by defining tasks that utilize data, automating workflows, or using autonomous technologies such as AI. “In other words, autonomy is letting data do the work, which can reduce human intervention,” Mr. Osaka said.

Hexagon defines itself as a digital reality company that promotes autonomy for industrial development. The company aims for automation through data utilization and further autonomy. First, looking at the current state of data utilization, which is the basis of autonomy, the amount of data generated has increased exponentially due to the trends of digitization, IoT, and Digital Transformation (DX). On the other hand, utilization of data has not kept pace. Data utilization is achieved by defining tasks that utilize data, automating workflows, or using autonomous technologies such as AI. “In other words, autonomy is letting data do the work, which can reduce human intervention,” Mr. Osaka said.

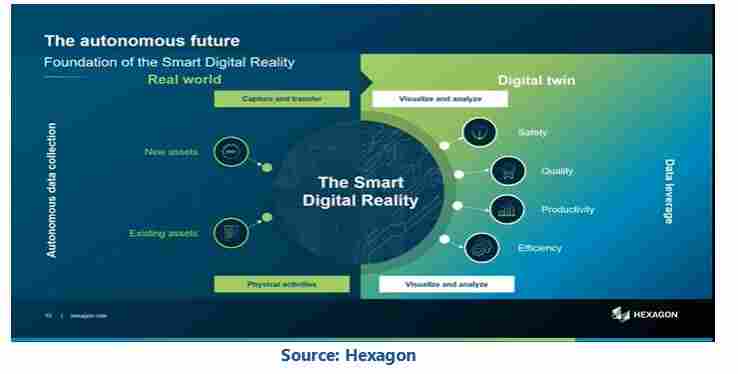

The role of autonomy is to put data to work, and Hexagon aims to build a feedback loop between the physical and digital worlds to bring that value to diverse customers across industries. This Smart Digital Reality feedback loop leverages five core technologies:

The Smart Digital Reality by Hexagon is a data utilization approach that integrates the real and digital worlds, and is shared by the company's nine divisions. But how does it work? First, data is collected by sensors from the real world, stored, transmitted, and linked. Next, the data will be used in the digital world. Data defines actions in the process of visualization, analysis, automation or autonomy, and drops them into activities in the real world.

According to Mr. Osaka the key phrases for this initiative are:

Two worlds, one reality — Where the real and digital worlds merge.

Workflow-driven — No matter what your business or industry is, workflow is important.

Real-time and autonomy — By capturing changes in a situation in real time and giving it more autonomy, it is possible to transform its function and practicality.

In the real world, data collection can be divided into two targets. One is new facility assets, by ingesting engineering data related to design, construction, etc., from various data sources. The other is existing equipment assets. In addition to engineering data, operation data of industrial equipment, production quality data, equipment management data, and various data utilizing IoT, and AI will be imported. These data are integrated, made smart into a unified format for ease of use, contextualized and then passed on to the digital world. In the digital world, data is visualized, analyzed, and workflows circulated to improve safety, quality, productivity, and efficiency, then put into action in the real world. In this manner, Smart Digital Reality forms a feedback loop between the real world and the digital world, even in manufacturing industrial equipment.

Smart Digital Reality, which creates value in terms of safety, quality, efficiency, and productivity, consists of two business process groups of Digital Projects and Digital Assets — and there is the third block, the Digital Backbone.

Digital Projects is divided into planning, design and execution of industrial equipment, and has seven core business process areas — portfolio & project planning, concept design, detailed design, procurement, material management, fabrication, and construction. Digital Assets is also divided into Operate, Maintain and Secure, and has seven major business process areas — operational excellence, process safety, workforce capability, managed equipment asset strategy, maintenance efficiency, sustained engineering, and OT/ICS cybersecurity.

The Digital Backbone is a technology that enhances business processes at various stages of the asset lifecycle, and consists of six functions, including interoperable connectors, common data environment, reality capture, digitization,  visualization, and analytics. The Digital Backbone integrates data from all sources, makes it smart, and provides visualizations and analytics tailored to specific roles and users within each business process area and connects to various data sources. These data are integrated, made smart for ease of use, contextualized on the Digital Backbone, and used for day-to-day business processes. Each business process avoids unnecessary duplication of functionality and data between related business processes, and enables seamless integration between Hexagon's solutions.

visualization, and analytics. The Digital Backbone integrates data from all sources, makes it smart, and provides visualizations and analytics tailored to specific roles and users within each business process area and connects to various data sources. These data are integrated, made smart for ease of use, contextualized on the Digital Backbone, and used for day-to-day business processes. Each business process avoids unnecessary duplication of functionality and data between related business processes, and enables seamless integration between Hexagon's solutions.

In the English track, Mr. Price’s thrust was on the company’s industry agnostic Enterprise Asset Management (EAM) solution. He reviewed the Hexagon solution, the different approaches, and applications in diverse industry verticals as an industry agnostic enterprise asset management system.

Hexagon purchased the Infor EAM product line in October 2021. Now called HxGN EAM, it is a cornerstone asset management solution that has been added to Hexagon’s Asset Lifecycle Intelligence portfolio. HxGN EAM provides the tools to help solve critical asset performance challenges. From its cloud-native foundation, with a robust asset data structure to device-independent work orders with barcoding, and GIS (Geographic Information System) or BIM (Building Information Modeling) capabilities, HxGN EAM provides the information when and where it is needed, to make better, more strategic decisions that extend asset life, ensure safety, and optimize profitability. “HxGN EAM has about 3,500 plus customers in its portfolio, which means that the company is looking at a wide array of assets in a wide array of industries,” said Mr. Price.

This product line will be useful for next-generation asset management. Different market trends are visible: a shift to SaaS, a resurgence of interest in reliability, predictive analytics, and advanced capabilities around sustainability. There are different types of solution integration needs; and different types of Internet of Things, connectivity, artificial intelligence that goes with the machine learning expansion out into the field within mobile solutions. These advanced types of capabilities and market trends are customized by Hexagon in a very specific manner by understanding the real world in a digital way and producing a digital twin. Within that, computing power, experience, and technique can be applied - essentially that is artificial intelligence that everyone wants to have. This helps to understand when issues are going to occur and have a proactive and predictive approach. It would be advantageous to know that your asset is in a certain risk variable before it occurs and take preventive measures to avoid future risk – laying the foundation of the Smart Digital Reality.

HxGN EAM synchronizes the visualization, analytical, connection tools and even the location tools to help bring new value within any asset type and is useful to customers across industries. This was explained via a video of an industrial facility that showed drilled down views, 2D & 3D views and the next steps (overlaying, hotspots, etc.). The graphic below shows the Smart Digital Reality that formed the crux of the presentations by Mr. Osaka and Mr. Price.

Hexagon has been in the digital projects space for about 50 years. The presentations in the Japanese and English tracks made it clear that Hexagon’s focus has been on bringing the real and digital worlds together from an asset management perspective. Hexagon combines not only the technical aspect of operation from a design and engineering and the throughput of production perspective, but also from a maintenance and operation perspective. This is possible because what it enables is not only the real-world definition of new assets, but existing assets as well; and this is done through the scanning engines and tools. Visualization of assets in industries such as transportation, manufacturing, oil & gas facilities, enhances operational levels.

ARC Advisory Group clients can view the complete report at ARC Client Portal

If you would like to buy this report or obtain information about how to become a client, please Contact Us

Keywords: ARC Industry Forum Asia, Enterprise Asset Management, Smart Digital Reality, Industrial Autonomy, Data Utilization, ARC Advisory Group.