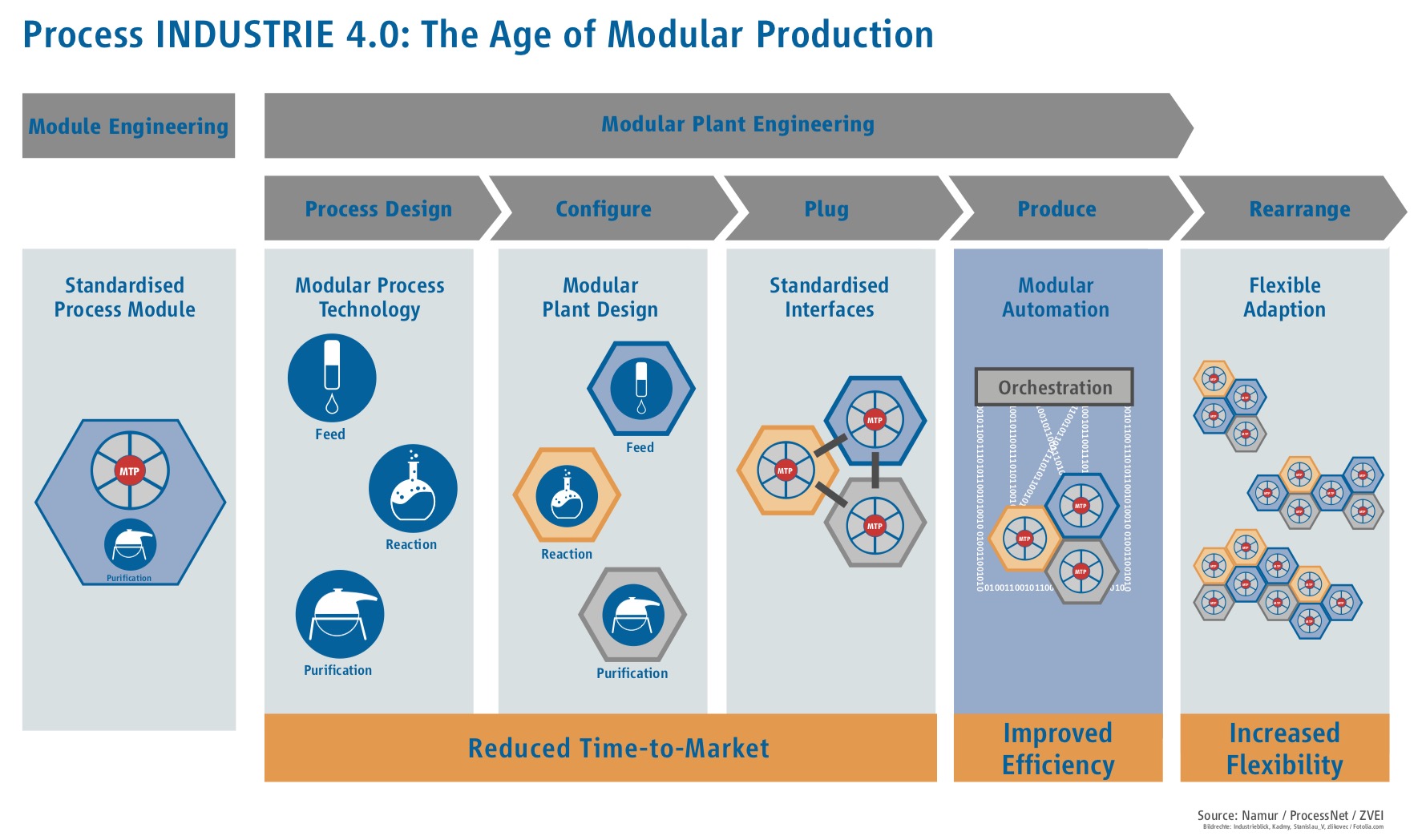

Automation vendors continue to support standardisation efforts initiated by NAMUR, with demonstrators and reports on pilot implementations of Module Type Package (MTP) that facilitates modular production. The impressive list*) of users, vendors, integrators and associations that participated in the common booth on MTP testifies on the perceived importance of modular production, and predicts significant rates of adoption of the standard. Major automation vendors demonstrated MTP at their stands (I personally saw MTP at ABB, Siemens, WAGO and Yokogawa).

The Siemens stand showcased a pilot implementation for a pharmaceutical pilot plant at (German) Merck. Process and automation engineering were done in COMOS where the “services” of the modules are defined and linked to the underlying automation. Examples of possible services are charging, heating, mixing, reacting, filtering, etc. Simulation of the automation structure and programming was done in SIMIT, that also generated the MTP files for each process module, which are subsequently imported in the process control layer or orchestration layer (here PCS7), where modules are connected in the order of the arrangement physical units. After this the process can be executed through the orchestration layer. Other providers offer similar mechanisms to engineer and export MTP’s.

This provides almost unlimited flexibility and significant time gains in reconfiguring the multi-purpose plant. In this particular example equipment is rearranged between test runs of different pharmaceuticals. In industrial scale or miniaturised plants, for both batch or continuous processing, the same would be possible between batches or campaigns of commercial products.

The approach also provides the possibility to integrate MTP’s from multiple vendors with very low effort in a compliant process control or orchestration layer. Users will have more choice in selecting equipment modules or package units, because they are not bound to an automation brand, and for equipment builders it would reduce cost and effort of configuration of equipment modules. The benefits show up during integration, reconfiguring and execution, but they are preceded by a one-time engineering effort per MTP, and a development effort by the vendors providing MTP engineering tools and import of MTP in their control systems.

MTP provides a layer of abstraction between the process automation and the orchestration layer, and the transparency a DCS provides is lost. The terms "process control layer" or orchestration layer are used to differentiate the approach from a classical DCS.

From the comments by most vendors, we understand it is still a challenge for them to accept the seamless integration of control sub-systems from the competition. Indeed it breaks with decades of virtual lock-in by the vendor after the initial choice of the user of a control system to use in a plant. What vendors do not seem to realize is that the increase in flexibility and cost reduction of engineering and integration that MTP provides, will improve the competitive position of the industry, favor innovation and this will lead to growth and investment, including investment in automation. The overall result maybe more positive for automation vendors than they imagine today.

*) ABB, BASF, Bayer, Clariant, Covestro, Emerson, Endress+Hauser, Evonik, Festo, Fraunhofer IPA, HIMA, HSU, Huber, Invite, Lanxess, Merck, NAMUR, Pepperl+Fuchs, PHOENIX CONTACT, ProcessNet, SAMSON, Siemens, SpiraTec, TU Dortmund, TU Dresden, VDMA, WAGO, Yokogawa, ZVEI

Source picture: https://www.zvei.org/fileadmin/user_upload/Presse_und_Medien/Publikationen/2018/Maerz/Process_INDUSTRIE_4_0_The-Age-of-Modular-Production_2018/FLYER__Modulare__Produktion_2018_20.02.18.pdf