Rockwell Automation has a tradition of holding its major global events towards the end of the calendar year to let its customers know what to expect from the company in the upcoming year and beyond. The company did so again last year with its 27th Automation Fair in Chicago, held in conjunction with its Process Solutions

Automation Fair featured about 150 Rockwell Automation and partner exhibits, 95 technical sessions, 20 labs, and nine industry-focused forums. Attendance was estimated at over 19,000 customers from 40 countries, which was a record for Automation Fair. A common theme of the events was Rockwell Automation’s continued advancement of “The Connected Enterprise” via digital transformation focused on products, solutions and services that help to simplify the complex to drive productivity.

Rockwell Automation’s Chairman and CEO, Blake Moret, opened Automation Fair for the global press and analyst community at the Automation Perspectives media/analyst event. Mr. Moret discussed the formation of the company’s Digital Partner Program, which connects companies to expertise and solutions from partners such as Accenture, Microsoft, PTC, ANSYS, and EPLAN. The goal is to help streamline the implementation and enhance the quality of digital initiatives. Through the Digital Partner Program, businesses can consult with industry advisors to create roadmaps for their digital initiatives and learn how Industrial IoT concepts, such as digital twin, the factory of the future, and a connected workforce can help to improve their uptime and efficiency. During implementation, businesses will have access to integrated hardware, software and turnkey systems from Rockwell Automation and these partners that will help to improve business performance leveraging their existing assets.

For example, under the Digital Partner Program, Rockwell Automation and Accenture Industry X.0 are collaborating to develop new solutions to help further optimize the industrial supply chain. To date, the collaboration has yielded a prototype for supply chain management designed to improve both cost and the ability to track the exact movements of products. Rockwell Automation will provide industrial automation technology and domain expertise, including FactoryTalk InnovationSuite IIoT software and analytics solutions. It will also bring network services, operational technology security, and application development, installation, integration and support. Accenture will provide enterprise business and technical capabilities, including consulting, analytics, application development, systems integration, change management and support.

Also discussed at Automation Perspectives was Rockwell Automation and Schlumberger’s new joint venture,

Progress was discussed regarding FactoryTalk InnovationSuite, a suite of integrated software solutions from Rockwell Automation powered by PTC. Over the past year there have been about 100 customer

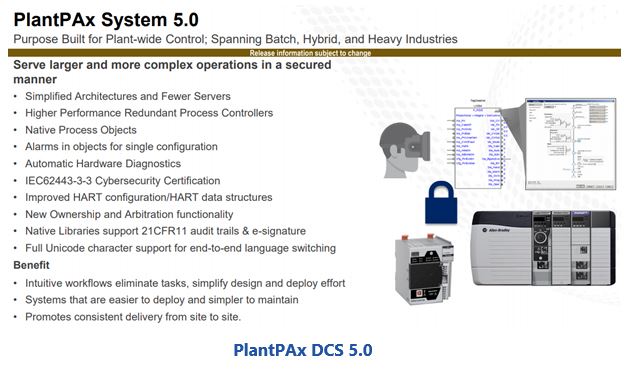

More than 1,000 customers participated in the 30 technical sessions at the Process Solutions User Group (PSUG). PSUG also featured 10 hands-on labs and 26 customer application case studies. A highlight of PSUG was the latest release of its PlantPAx distributed control system (DCS), focused on providing specifically tailored solutions throughout each phase of the plant lifecycle. The release is planned for the summer of 2020. This new release of the PlantPAx 5.0 DCS is focused on solutions for productivity gains in multiple areas of the plant, using a more simplified approach to control system strategies. In this release, Rockwell Automation introduces new process controllers that help improve scalability and skid integration, as well as provide a more simplified, lower-cost architecture due to higher controller performance. Embedded native process objects help reduce engineering costs and drive more consistency in projects. New cybersecurity capabilities and system certifications help ensure safer and more secure operations.

Another solution highlighted at PSUG was the upcoming FactoryTalk Batch release designed to address industry challenges in operational lifecycles. A key feature of the new release is enabling users to make online edits for plant areas that require a higher degree of control and flexibility while remaining in production. As needs change or as custom recipes are introduced, operators can make changes without having to take portions of the system offline or placing the batches on hold. Additionally, more complex operations will be able to create dynamic flows and recipes with the introduction of formulations to provide options to help improve throughput and yield. Additional improvements focused on mobility, more secure architectures, and data integration tools to help with addressing changing workforces and the ongoing needs for enterprise intelligence.

Presentations at PSUG included a keynote from GE Healthcare, which cited that by 2022, biopharmaceuticals will make up 30 percent of all prescriptions. This requires advanced automation to be deployed in bioprocesses to reduce downtime, maximize yield, reduce maintenance, minimize regulatory exposure, and provide cybersecurity protection. This led GE Healthcare to partner with Rockwell Automation to develop its “Figurate” automation and digital platform. According to GE Healthcare, the platform’s automation, MES, and operations performance management solutions have resulted in 10 to 20 percent increases in production throughput, availability, and production employee efficiency, with 5 to 30 percent decreases in energy usage, scrap, batch release times, and maintenance downtimes. Benefits of the platform’s asset performance management solutions have resulted in a 5 to 10 percent decrease in parts inventory costs, a 10 to 40 percent reduction in reactive maintenance costs, and a 5 to 25 percent gain in maintenance employee productivity. Benefits of related services have resulted in a 9 percent increase in equipment uptime, a 13 percent decrease in compliance incidents, and a 9 percent decrease in service costs. GE Healthcare’s next step is to work with Rockwell Automation and PTC to incorporate augmented reality (AR) solutions into the platform.

Several of the 26 application case studies presented at PSUG included:

One of the main attractions of Automation Fair is the opportunity for attendees to receive free training in the technical sessions, labs, and industry-focused forums. The industry forums were Automotive and Tire, Chemical, Food and Beverage, Life Sciences, Material Handling, Metals and Mining, OEM, Oil and Gas, and Water/Wastewater. For example, at the OEM Industry Forum, the theme was workforce enablement and the new age of OEM value, with presentations from Rockwell Automation, Kraft Heinz, 3V Automation, PCMC,

OEM Forum discussion focused on the issues, such as the fact that in the past, manufacturing focused on automation improvements to fill in the skill and workplace gaps. However, today advanced and emerging technologies along with digital transformation are required to make up for the skill and workplace shortages. Traditional equipment does not fit today’s needs, as there are growing expectations for OEMs to maximize uptime and equipment optimization, which is critical to remain profitable. OEMs must seek new opportunities to leverage these technologies and digital transformation such as by offering services that can monetize the full lifecycle support of their equipment. OEMs should be providing information based on real-time production data, leveraging technologies, such as Industrial IoT for remote performance monitoring, troubleshooting for decreased downtime, and providing technologies such as AR to deliver digital work instructions to increase the productivity and performance of the new workforce.

Cybersecurity was a prevailing theme throughout Automation Fair. To further supplement Rockwell Automation’s capabilities, the company recently announced that it has signed an agreement to acquire Avnet Data Security Ltd, an Israeli-based cybersecurity provider with over 20 years of experience providing

The Connected Enterprise is designed to help companies converge plant-level and enterprise networks, and more securely connect people, processes, and technologies to help drive digital transformation. To further

Solutions exhibited and displayed at Automation Fair help further enable The Connected Enterprise. These include visualization and control hardware and software and IIoT gateways that can integrate smart devices,

The many exhibits, sessions, customer case study presentations and partnership announcements at the combined PSUG, Automation Perspectives, and Automation Fair event helped demonstrate how Rockwell Automation continues to advance its vision of The Connected Enterprise through digital transformation. The record attendance demonstrated the soaring interest in digital transformation and The Connected Enterprise. ARC looks forward to seeing additional digital transformation success stories in 2020 and beyond, and seeing the benefits customers are deriving as a result of the new solutions created by the Rockwell Automation PartnerNetwork.

ARC Advisory Group clients can view the complete report at ARC Client Portal

If you would like to buy this report or obtain information about how to become a client, please Contact Us

Keywords: Digital Transformation, Connected Enterprise, Digital Partner Program, Accenture, ANSYS, Sensia, PTC, Avnet, Kalypso, ASEM, Automation, ARC Advisory Group.