Summary

Recipe management plays an important role in the success of batch manufacturing, often representing a key component in a company's manufacturing operations transformation process.

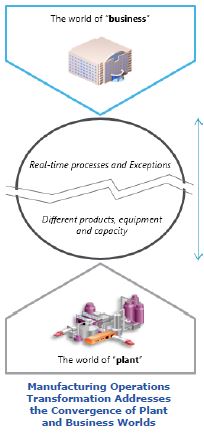

Manufacturing operations transformation involves many of the same aspects as broader business transformation. These include a reducing the number of applications deployed, master data management, centralized management and support of applications, global digitization platforms, standardized process and global best practices, plus performance management and KPIs. Specific benefits associated with manufacturing operations transformation often include improved equipment, unit and product consistency; faster time to market; quicker deployment of product changes; greater manufacturing flexibility; increased innovation; and improved product quality and consistency. A consistent and governed approach to recipe management across an enterprise is essential, as business's look to safeguard their product quality and safety and leverage their supply chain.

Manufacturing operations transformation involves many of the same aspects as broader business transformation. These include a reducing the number of applications deployed, master data management, centralized management and support of applications, global digitization platforms, standardized process and global best practices, plus performance management and KPIs. Specific benefits associated with manufacturing operations transformation often include improved equipment, unit and product consistency; faster time to market; quicker deployment of product changes; greater manufacturing flexibility; increased innovation; and improved product quality and consistency. A consistent and governed approach to recipe management across an enterprise is essential, as business's look to safeguard their product quality and safety and leverage their supply chain.

Recipe management is an integral part of a batch management solution. However, a huge gap exists in the market between the simpler recipe management solutions offered in many HMI/SCADA software packages and full blown batch management and control packages. While many manufacturers may not have the functional need, resources, funding, or time to deploy and support batch management and control solution, recipe management functionality is still important to enable the manufacturer to manage product recipes and formulas for product quality, consistency, and governance purposes. This is especially true in the consumer products, food & beverage and specialty chemicals industries.

Recipe Management Critical to Batch Market

Specific challenges faced by many batch process manufactures include improving quality, batch-to-batch consistency, minimizing waste, lowering costs, increasing throughput, and improving ROA. The complex nature of most batch processes and variations in materials usage and process settings between products produced make them difficult to control and optimize, requiring sophisticated recipe-driven production techniques to maintain batch-to-batch consistency, increase flexibility, shorten product release cycles, reduce lead times, cut costs, better manage global operations, and produce products that meet or exceed customer expectations.

Who Needs Recipe Management?

Recipe management is a key component of manufacturing operations transformation because many people throughout a company require easy access to recipes and/or product and raw material specifications data to do their jobs.

Standards-based batch manufacturing and batch management software have both improved dramatically, due in part to international standards such as ISA-88. However, automation suppliers must continue to improve and adapt their solutions to meet constantly evolving manufacturing requirements and the dynamic nature of raw materials, water availability, energy costs, and other inputs; as well as the changing composition of the labor force. Recipe management solutions that fill the gap between HMI/SCADA and full batch management can help.

Wonderware Recipe Manager Plus

To address this gap between HMI/SCADA software packages and full batch management packages, Schneider Electric developed Wonderware Recipe Manager Plus, an automation system-neutral recipe management and execution software offering. It is designed to help operational teams collaborate in recipe adoption and to optimize execution on automated production and packaging equipment. The software offers a ready-to-use, web-based user interface for recipe and formulation management and execution. It offers governance functionality, including configurable role-based security, automatic item versioning, and an electronic change and execution history. Users can connect with existing production equipment control systems via either OPC UA or seamless integration with Wonderware System Platform. The platform-neutral user interface is available on any computer, operator panel, or mobile device that offers an HTML5-compatible browser.

Wonderware Recipe Manager Plus software offers two solution options. The Standard Edition for formula management provides the functionality to manage set up of production and packaging machines producing a specific product by downloading the product formula parameter values to the equipment control system.

Wonderware Recipe Manager Plus software offers two solution options. The Standard Edition for formula management provides the functionality to manage set up of production and packaging machines producing a specific product by downloading the product formula parameter values to the equipment control system.

The Professional Edition adds procedure management functionality for both formula and recipe management. This provides automation and repeatability of production processes to recipe specification on production units, work cells, or line equipment. In addition to downloading formula parameter values, the Professional Edition manages procedure execution, exchanging commands and status information with the equipment control systems.

What Value Does Recipe Manager Plus Bring to Customers?

Wonderware Recipe Manager Plus provides a combination of recipe management and user interface functionality. According to the company, the software can be used by process engineers and recipe administrators as well as plant operators to manage multiple product variations and execute product changeover processes to help maximize production output. Features including role-based security, automatic item versioning, approvals for production use, and electronic history records that provide governance to secure consistency of quality and processes and help to lower the cost of regulatory compliance.

Wonderware Recipe Manager Plus is designed to standardize recipe management in automated manufacturing operations across a company's businesses and often heterogeneous automation system landscapes. Standardization across equipment, multiple lines, or plants can help speed up the new product introduction processes and time-to-market.

Wonderware Recipe Manager Plus vs. HMI/SCADA, Batch Management, and Custom Solutions

HMI/SCADA Recipe Management

Many HMI/SCADA packages, including Schneider Electric's own Wonderware InTouch software, offer tools to download formula parameters to control systems. These HMI/SCADA-based recipe parameter management tools, often used as part of a machine's HMI solutions delivered by the OEM, typically offer limited governance to manage editing rights, versioning, and history of recipes. Many are tied to a particular HMI/SCADA product and not system-independent. Their user interfaces and recipe definition approaches tend to be more technical in nature, often making them difficult for people in the recipe authoring role to master.

Many HMI/SCADA packages, including Schneider Electric's own Wonderware InTouch software, offer tools to download formula parameters to control systems. These HMI/SCADA-based recipe parameter management tools, often used as part of a machine's HMI solutions delivered by the OEM, typically offer limited governance to manage editing rights, versioning, and history of recipes. Many are tied to a particular HMI/SCADA product and not system-independent. Their user interfaces and recipe definition approaches tend to be more technical in nature, often making them difficult for people in the recipe authoring role to master.

Batch Management

Similarly, most of the major automation suppliers offer full batch managements systems that compete with Wonderware InBatch in the same solution space. These focus on managing high-value batch processes in industries, such as life sciences and specialty chemicals. Batch management systems commonly offer ISA-88-compliant recipe modeling, batch scheduling and batch execution, electronic batch records (EBR) with security, and governance to enable compliance to FDA and GMP regulations. While very capable, these full batch management systems often represent significant "overkill" for many recipe management applications and drive a structured approach to process control that is often beyond the needs of manufacturers.

Custom Solutions

A third common option, custom-made recipe management solutions developed and provided by system integrators help fill the gap between HMI/SCADA-based recipe management tools and full batch management to a certain degree. However, the high degree of customization required makes these costly and unwieldly for manufacturers to support over time.

Wonderware Recipe Manager Plus  As a standalone, HMI- and system-independent recipe manager solution, Wonderware Recipe Manager Plus software was designed specifically to fill this gap. It offers scalable, largely off-the-shelf formula and recipe management functionality with collaborative, multi-user capabilities with central data management. It is a fully web-based server application with built-in user interface functionality: role-based security; and automatic versioning, approval and change history functionality. These capabilities can help improve innovation and reduce time-to-market for recipe changeovers and new product recipes or versions.

As a standalone, HMI- and system-independent recipe manager solution, Wonderware Recipe Manager Plus software was designed specifically to fill this gap. It offers scalable, largely off-the-shelf formula and recipe management functionality with collaborative, multi-user capabilities with central data management. It is a fully web-based server application with built-in user interface functionality: role-based security; and automatic versioning, approval and change history functionality. These capabilities can help improve innovation and reduce time-to-market for recipe changeovers and new product recipes or versions.

Recipe Manager Professional Edition adds execution capability that can be easily overlaid onto existing control sequences, without the need to restructure existing controller and OEM code into S88 phases.

According to the company, one user estimated a 40 percent improvement in engineering efficiency and 20 to 40 percent production improvement when introducing new products compared to its previous systems.

Conclusion

Manufacturers should review, evaluate and determine their real needs when it comes to batch and recipe management. They should carefully consider whether a full batch management solution is required or if a standalone recipe management solution could provide a more appropriate, cost-effective, and easier-to-use solution. If the latter, it appears that Wonderware Recipe Manager Plus can provide a standardized, platform-independent, largely out-of-the-box solution; one designed to provide a variety of users across the business with secure access to the recipe and formula information they need to do their jobs.

All signed-in ARC Advisory Group clients can view this report in pdf format at this Link

If you would like to buy this report or obtain information about how to become a client, please Request ARC Info

Keywords: Recipe Management, Batch, Manufacturing Operations, Transformation, ARC Advisory Group.