ARC attended and presented at the Yokogawa Asia Pacific Users Conference held earlier this month in the city of Bandung in Indonesia. As well as witnessing the first worldwide public launch and discussion of the company’s new Synaptic Business Automation concept plus informative presentations by customers from mainly Indonesia, Malaysia and Singapore, the event provided a timely opportunity to get up close to Yokogawa’s array of process automation technology – control and safety systems, asset management systems, operator training simulators, analyzers, wired and wireless instrumentation, and more.

Wireless instruments targeting the process industries first hit the market a decade ago, followed very quickly by the (in)famous wireless wars, where proponents of WirelessHART on one side and ISA100 on the other lobbed metaphorical missiles at each other (often via the trade media) as they sought to convince users of the superiority of their own technologies.

While the battle ended in a stalemate and the goal of a single industrial wireless standard remained elusive, it turned out that users did not much care, with the clear benefits of wireless instruments – notably, bringing sensing to places in the plant where it was previously too costly or complicated to install wired infrastructure – sufficient to trump the lack of a universal standard.

So wireless essentially went mainstream in the plant, although much more for monitoring than critical control, and process instrumentation suppliers, including Yokogawa (a long-time ISA100 proponent), now routinely offer devices conforming to either the IEC 62591 (WirelessHART) or IEC 62734 (ISA100) international standard. More recently, and likely not anticipated back in 2008, the Industrial IoT boom has brought new prominence and importance to sensing technology and capability in the plant, and suppliers now often couch their wireless offerings in the broader context of enabling IIoT.

Back at the Yokogawa Users Conference, industrial wireless offerings on show included several wireless pressure and temperature transmitters, the GX20W wireless paperless recorder, the ProSafe-RS SIL2 wireless gas detection system, the WiSense wireless corrosion sensing system, and the Sushi Sensor. Yes, Sushi Sensor. It’s the name for a new wireless product that Yokogawa has heralded for some time but is finally set to see release in next month, first in Japan and then other countries at a later date.

But why the name, Sushi Sensor? Yokogawa explains: "Sushi is easy to eat. People can enjoy different types of Sushi e.g. nigiri, maki rolls, and ingredients e.g. salmon, tuna, shrimp. A professional Sushi chef makes tasty Sushi and makes customers happy. Our sensor is like Sushi and Yokogawa is like a professional Sushi chef; therefore, we call the sensor Sushi Sensor."

While Yokogawa’s ISA100 devices target collecting and transmitting process data in order to improve plant operation efficiency and safety performance, the Sushi Sensor focuses on plant assets, simultaneously measuring vibration and surface temperature of equipment with the objective of optimizing the maintenance function as well as energy management.

Salient features of the device include easy and quick installation in different parts of the plant; waterproof and dustproof (IP66/67); explosion proof; and long battery life. The Sushi Sensor is not available for sale as a single product but as part of a Yokogawa Industrial IoT solution.

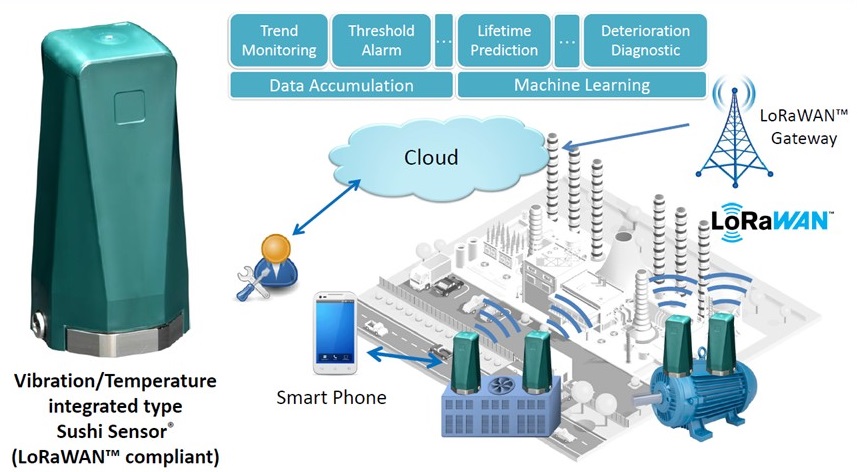

Unlike those ISA100 wireless devices, which communicate their data to the control system, the Sushi Sensor connects directly to the cloud, where the asset data can be operated on by machine learning based analytics software in order to, for example, provide early warning of asset problems and impending failure.

Interestingly, that connection is via LoRaWAN, one of the low-power wide area wireless networks (LPWANs) that are coming to the fore and seeing deployment in IoT applications involving large numbers of devices and where the onus is on long sensor battery life and low implementation cost.

During the Yokogawa event in Bandung, company executives informed ARC that the Sushi Sensor is implemented in some of Yokogawa’s own manufacturing plants to, among other things, monitor compressor vibration. Customers are encouraged to come and see how the data is collected/analyzed, and also to better appreciate the role these IIoT sensors play within Yokogawa’s new Synaptic Business Automation concept. Aside from temperature and vibration, Yokogawa plans to provide other types of Sushi Sensor in the future to cater for more customer needs in the area of plant asset management.